Surface Mount Pad Repair

What Repair Services Do We Offer?

More than 25 years of experience makes our staff well-versed in an array of problems, including:

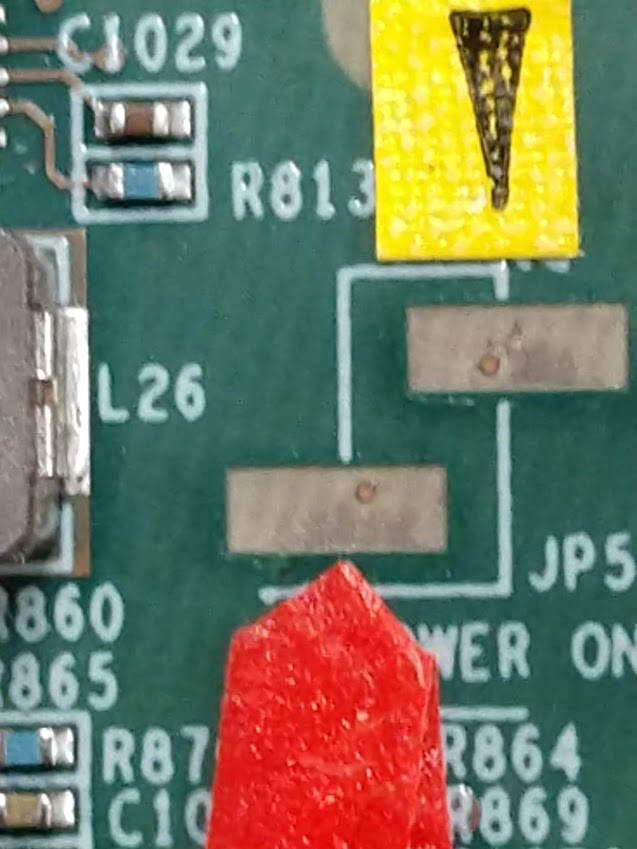

- Standard SM Pads: These pads can suffer damage when its respective device separates from the PCB. We can carefully remodel the pads by cleaning the area, removing the defective component and taking off the solder mask from the connecting circuit. From there, we'll take an appropriate, commercially graded replacement pad, cut it out and clean it up, then securely fit it into the vacant spot. We'll measure the pad to ensure an exact fit and evaluate by performing an electrical continuity test.

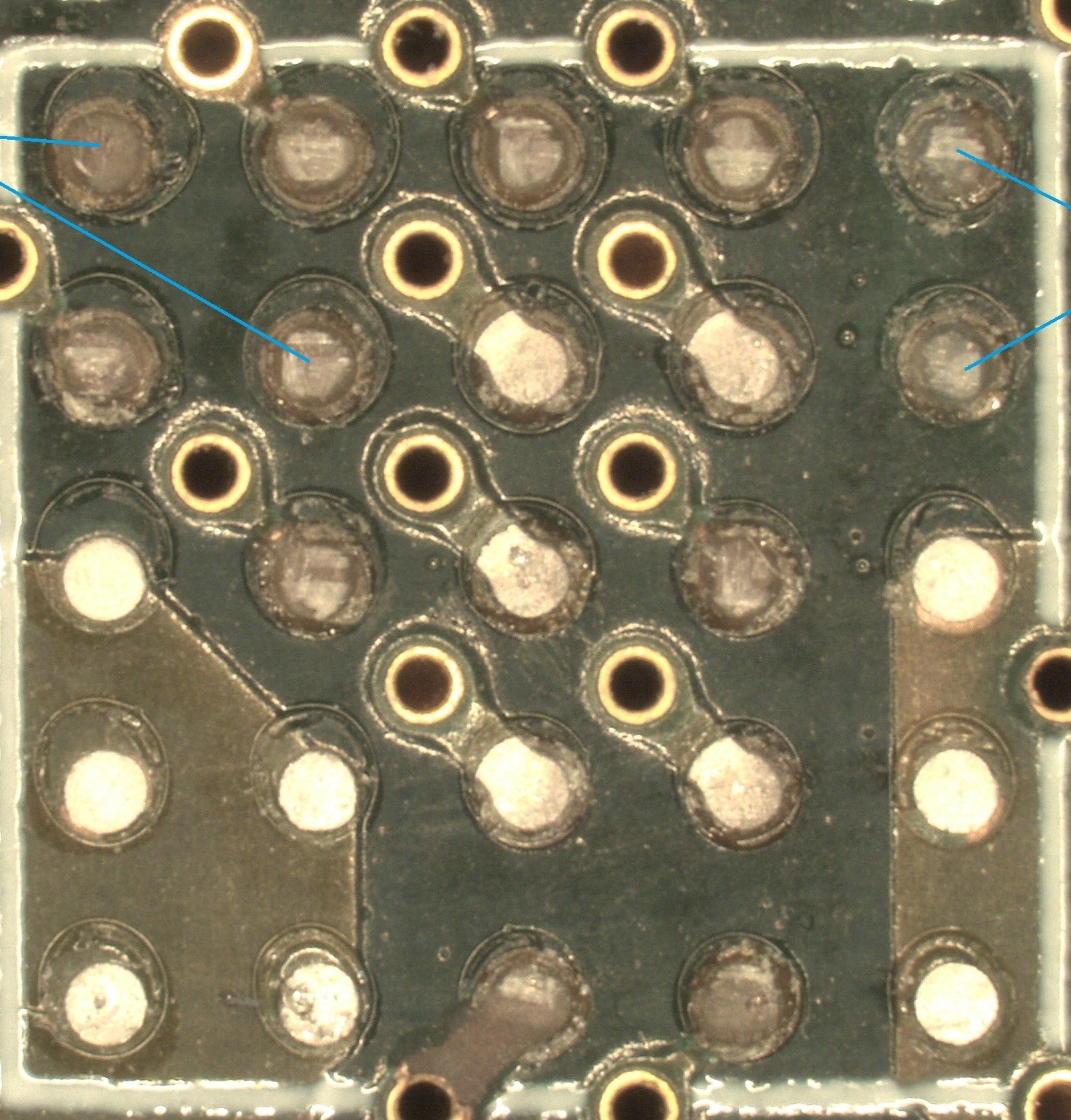

- SM Pads With Buried Vias: Buried vias, which connect two or more outside layers to an inside layer, can be quite useful in intricate PCB designs that require a higher number of components over a smaller surface area. Drilling vias into surfaces do not affect trace, and you can cover them using SM pads. That said, you'll need to monitor the depth of peck drilling carefully, as a hole too shallow or too deep can negatively affect the integrity of the board. We can remove and replace defective surface mount pads while analyzing the effectiveness of a via.

- BGA Pad Repair: A ball grid array is a type of SMP that can be particularly difficult to rework and repair. BGA pads are more prone to mistakes, like excessive solder joint voiding and bridging, but we can avoid these issues with proper analysis, planning and execution. By removing the defective pad and preparing the via for a new connection — which includes laying the connected circuit into the trough — we can seamlessly integrate the new component using a bond system.

- Gold Finger Contacts: Gold fingers are one of the most vulnerable components on a circuit board due to their location on the circuit board's periphery. In addition to possible physical damage from integration and removal, gold fingers are also susceptible to solder splash. As part of our gold finger repair services, we'll carefully inspect the components to determine the extent of the damage. We will move forward with the result that gets your parts back quicker and reduces your downtime. We can fabricate new finger contacts to replace high-volume components, or we can refurbish the existing ones by re-plating them, which requires stripping them down to the bare metal and electroplating them.

The SMT Pad Repair Process

How exactly do we repair your circuit board if one or more of your pads is lifted or missing? While the process of SMT pad repair is not an extremely complicated one, you can have very poor results if it is done incorrectly. For this reason, if you have not been specifically trained in SMT repair, this type of work is best left to professionals like those at Precision PCB Repair.

The steps we take to repair a lifted solder pad or to replace a missing solder pad are as follows.

- Step One: Assuming the pad is still there, hanging partially on the board, we carefully remove the pad and clear any debris from the surface of the board. This includes getting rid of any solder on the connecting circuit.

- Step Two: We find a new surface mount pad of the correct size and shape to match the old pad in order to perform a replacement.

- Step Three: We scrape off any excess adhesive bonding film from the back of the new pad, then trim the new pad to make sure it fits the board exactly, including some connecting circuit to overlap the circuit still on the board. This allows us to make a lap solder connection.

- Step Four: We position the new pad with the help of a special piece of tape to ensure proper alignment.

- Step Five: We then bond the new pad to the board, using heated bonding tips to create a heat and pressure seal between the pad and the board.

- Step Six: We lap solder the joint, if necessary, then coat it with a strong, temperature-resistant epoxy to fully bond the pad to the board.

- Step Seven: We repeat the steps as many times as necessary to repair or replace all the lifted or missing pads on the board.

- Step Eight: We return the repaired board to you, all pads in place, ready to service your applications.

What Causes a Lifted Pad?

You know how we perform SMT pad repair, but how do you end up with a missing pad or lifted solder pad in the first place? Typically, you will get a lifted pad situation when you are trying to de-solder components from your printed circuit board. Most of the time, you will notice and be able to take steps to deal with the problem right away.

Other times, wear on the board may leave you with a detached solder pad. If you work the joint enough, it is possible that you will neutralize the adhesive bonding between the copper and the board and end up with a lifted or missing pad. This is more likely to occur if your board has thin copper layers without through-plating on the holes, so it is often worth it to invest in through plating, especially if your board has thin layers.

Trust Precision PCB Services With Your Next Repair

The machining of electrical components is time-consuming and requires precious resources, so no company should tell you that any one part is unsalvageable. Precision PCB Services uses extensive knowledge and a measured approach to rectify defective components, all while providing intensive, detailed customer service that aims to give you the best experience. Contact us today to inquire about our repair and reworking services.

Finely tuned electronics need to be free of defects and damage to function correctly, and it requires deft hands and keen knowledge to complete repairs and reworks.

Precision PCB Services can fulfill your requests, as we'll put your components through a detailed process to eliminate problems and ensure peak efficiency. We offer the expert repair of surface mount pads and other electronics in accordance with IPC Standards since 1991.

- Standard SM pads

- SM Pads with buried vias

- BGA pads

- Gold finger contacts

Finely tuned electronics need to be free of defects and damage to function correctly, and it requires deft hands and keen knowledge to complete repairs and reworks.

Precision PCB Services can fulfill your requests, as we'll put your components through a detailed process to eliminate problems and ensure peak efficiency. We offer the expert repair of surface mount pads and other electronics in accordance with IPC Standards since 1991.

- Standard SM pads

- SM Pads with buried vias

- BGA pads

- Gold finger contacts